Welcome to Panjin Shunsheng Petroleum Technology Co., Ltd.

Buried pipe stress centralized detection system

Product introduction

Catalog

I. Brief introduction of non-contact magnetic measurement diagnosis technology

2. System host

3. Select the scanning device as required

4. MM-System Graphic Software for Metal Magnetic Memory Method Stress Concentration Detection System

5. Brief description of the process of using metal magnetic memory method to detect buried pipelines

6. Application Scope of Buried Pipeline Stress Concentration Detection System

7.Detection cases using this technology:

Buried pipeline stress concentration detection system

I. Brief introduction of non-contact magnetic measurement diagnosis technology

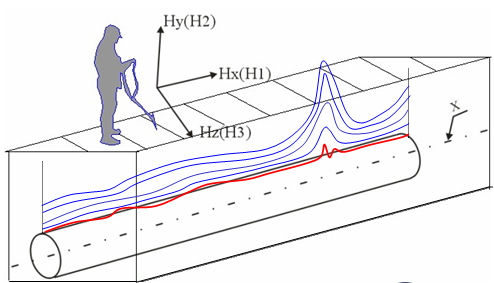

The invention relates to a buried pipeline stress concentration detection system, which uses a metal magnetic memory detection theory to detect a buried pipeline, and has the basic principle that after a metal component is corroded and fatigued, the internal grain structure of the metal is changed, the average internal stress level caused by the inhomogeneity of the organizational structure is uneven, and a self-leakage magnetic field is generated in a stable sliding dislocation zone, An object to be inspected is detected in the environment of the earth's magnetic field,There is a strong magnetic field gradient in the stress concentration area, and the non-contact magnetic diagnosis is based on detecting the change of the earth magnetic field distortion formed by the change of the magnetic permeability of the pipeline metal in the stress concentration area and the corrosion-fatigue damage growth area. The working principle of the instrument is to measure the distribution of the magnetic field Hp of a detected object, establish that the relationship between the distribution of the magnetic field Hp and the residual stress is the strength value and the change characteristic of the normal component and the tangential component of the leakage magnetic field measured right above the ground surface of the detected pipeline by using a special scanner,To evaluate the stress concentration and deformation state of pipeline or equipment structure, analyze the change of metal structure, and find out the method of defect. Using the metal magnetic memory non-contact magnetic detection method to detect the buried pipeline can find out and locally locate the stress and deformation state and various types of damage existing in the pipeline metal under the ground, underwater or other media.

The non-contact magnetic diagnosis is based on the detection of the time variation of the earth's magn

When the pipeline condition information is diagnosed according to the non-contact magnetic measurement method, the analysis can be carried out according to the criterion and software package developed by the metal magnetic memory method. The method can be used for comprehensive evaluation of the pipeline condition, and can also be used together with other non-destructive testing methods for evaluation

Estimate.

Non-contact magnetic diagnostic method is a new technology for nondestructive testing of oil and gas buried pipelines, which can determine the metal state of buried pipelines. The detection speed is high, the detection cost is low, a large amount of excavation work is not needed, and only the position with the abnormal distribution of the magnetic field needs to be excavated for verification. There is no need to remove the anticorrosive coating on the pipeline for excavation verification, and the metal magnetic memory method can detect the metal state of the pipeline body without removing the anticorrosive coating.

The main objectives of the contactless magnetic diagnostic method are:

Under the condition of not changing the technology and function of oil and gas pipeline, the pipeline section which works under the maximum stress and has the tendency of damage is determined.

Determine the excavation location for supplementary detection by metal magnetic memory method or other non-destructive testing methods.

2. System host

1. Host of stress concentration detection system

The stress concentration detection system is a system that uses metal magnetic memory method to measure, record and process the diagnostic data of stress and deformation of equipment and structure. It is used to evaluate the stress and deformation of the equipment according to the special detection method and determine the stress concentration area. The working principle of this instrument is to measure the distribution of the magnetic field Hp on the surface of the object to be tested. The magnetic field intensity is measured in A/m (amper

The relationship between the distribution of magnetic field Hp and residual stress has been established by this series of instruments. The instrument, together with the developed detection methods suitable for different industrial sectors, provides a new principle and means for the diagnosis of equipment in operation. This instrument is suitable for contact detection of pipelines, non-contact detection of buried pipelines, and other large structural parts.Detect.

2. Instrument features:

● Single-component, two-component and three-component sensors are supported to measure the normal and tangential components of the magnetic field at the same time;

:●. Large color LO display with 800 X 180 resolution allows for more intuitive viewing of data without transferring it to a computer.

● The 45-key keyboard inputs characters and controls the instrument with 7 additional shortcut function keys to simplify the operation:

● The screen directly displays the parameters of each channel, magnetic field distribution map and gradient distribution map:

● It can calculate the d positive figure and calculate the difference gradient of adjacent channels.

● Up to 32 measurement channels, with three recording length detection modes of point measurement, encoder counting and time counting:

● Multi-channel operation, more than a dozen scanning devices can be selected, wide range of applications: different detection purposes can be achieved by replacing the probe

Can be connected to a dedicated scanning device to detect buried pipelines:

Using the natural magnetic properties of metals, no special magnetization of the object to be tested is required:

● No preparation is required for the surface to be inspected, and the inspection can be conducted through the coating;

● Be able to determine the location of metal stress concentration area and defects, and realize the early diagnosis of defects:

● Detection data can be stored and transmitted to the computer:

● 256m storage space, which can save sever

Agency for Drilling and Workover Engineering Technical Services

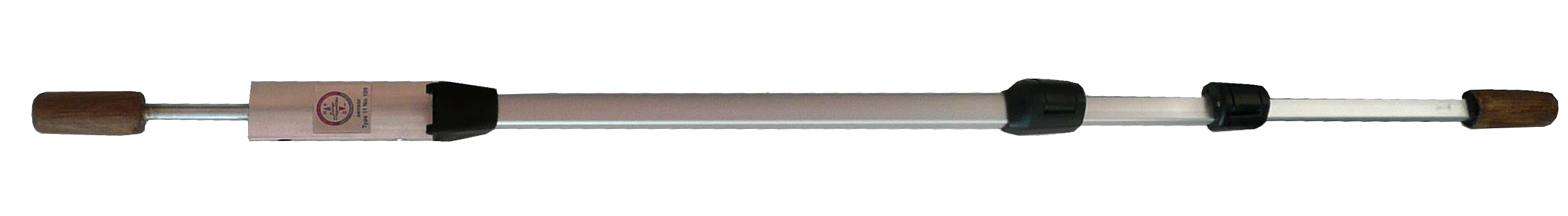

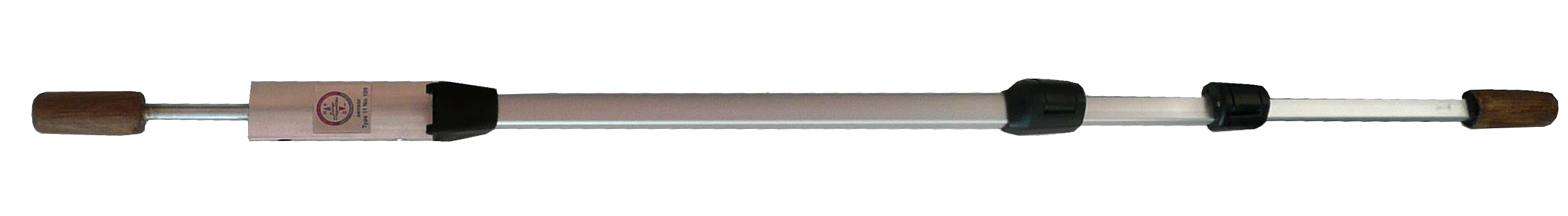

2) 11-6W: Non-contact probe for Trenchless detection of buried pipelines, trial use of large diameter pipeline detection 11-6W scanning device is a special high-sensitivity scanning device integrated with three-component magnetic detection sensor and analog-to-digital converter. The special scanning device for 6-channel underground pipeline detection is suitable for detecting pipelines with a diameter greater than 530 mm. Can be used for underground oil with the depth of 2 to 3 meters,Contactless magnetic memory diagnosis of gas pipelines. Dedicated high-sensitivity scanning device with two 3-component sensors and an analog-to-digital converter. Resolution 0.1A/M. The normal component and that two tangential component of the magnetic field are respectively measured, the two sensor are arranged according to the height, and each sensor comprises three measurement channel. The scanning device is designed as a telescopic rod type, the length of the scanning device is adjustable, the scanning device is provided with a fastening device and a counter interface, and the scanning device is designed as a telescopic rod type. An external counter can be used to measure the length during detection.

3) Contact detection of pipeline after excavation

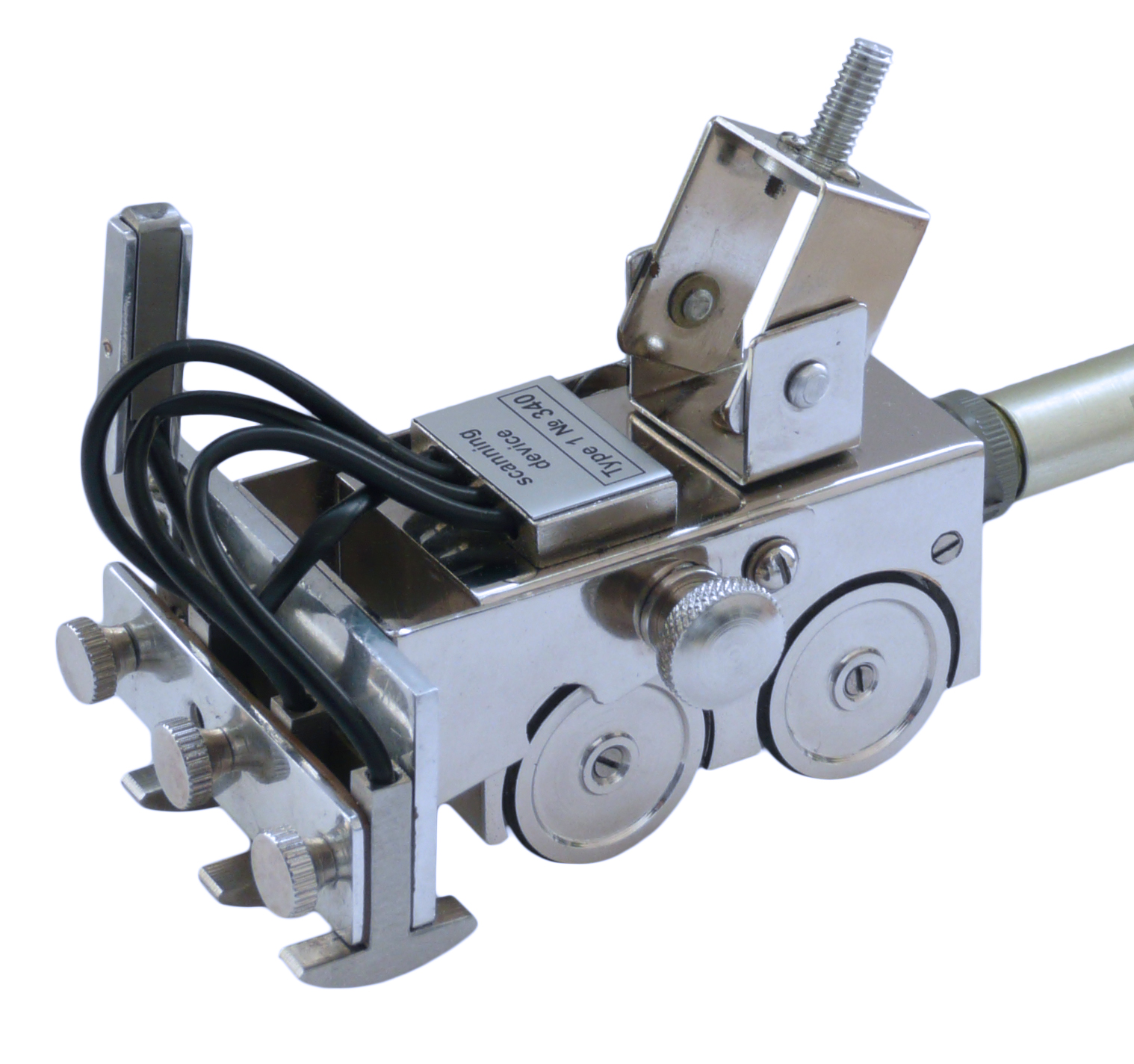

Contact inspection and weld inspection: use 1-8M scanning device

8-channel contact seam inspection scanner. Four two-component magnetic detection sensors are used to measure the normal component and a tangential component of the magnetic field respectively, which are used to quickly scan the local stress concentration of the pipeline weld. The scanning device is designed in the shape of a trolley, four sensors are horizontally arranged, and each sensor contains two measuring channels. Sensor spacing, height, direction can be based on the pipe orThe shape of the weld is adjusted with a locking structure. The cable is 1.5 meters long and has an integrated 4-wheel counter to record the detection length.

By measuring the two hyperfield components of the magnetic field at the same time, more comprehensive data can be acquired, and the detection effect during key lifting detection is improved.

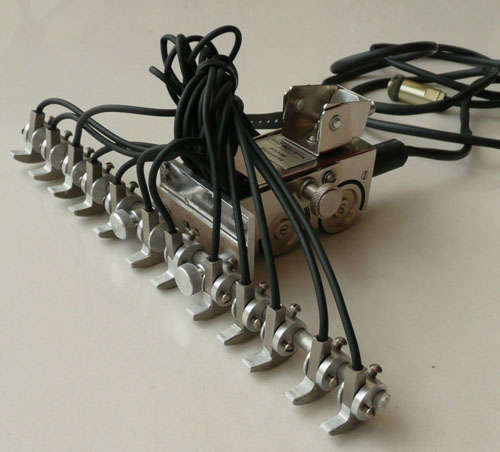

4) Large-area high-efficiency contact detection after excavation: use 6-12 type scanning device

12-channel contact-type large-area contact-type detection device with a single scan width of up to 20 cm. 12 single-component magnetic detection sensing

The scanning device is designed in the shape of a trolley, 12 sensors are arranged horizontally, the spacing, height and direction of the sensors can be adjusted according to the condition of the pipeline, and the device has a tight structure. Aluminum support rod, the sensor can be installed on the self-made support rod with different radian according to the diameter of the pipe to adapt to different pipe diameters. The cable length is 1.5 meters. Four wheel linkage encoders are used to record the detection length.

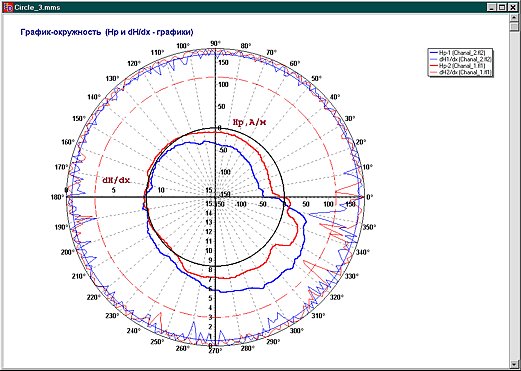

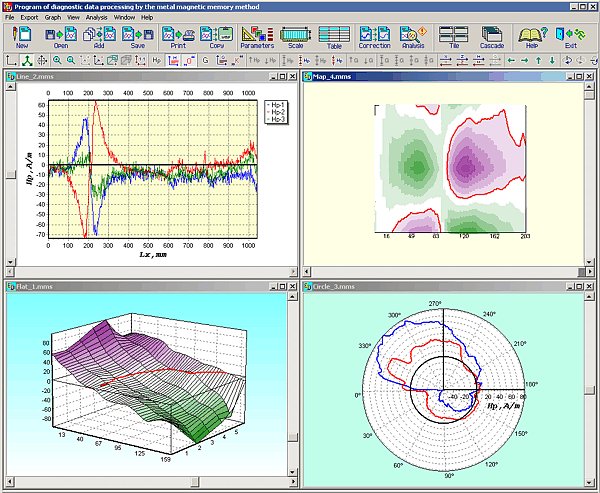

4. MM-System Graphic Software for Metal Magnetic Memory Stress Concentration Detection System

The software M-System is used to deal with the stress and deformation of parts, equipment and structures obtained by metal magnetic memory method.Data.

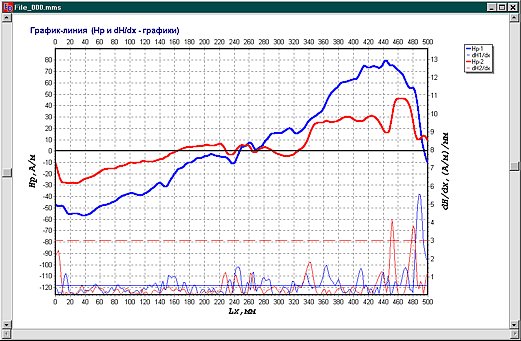

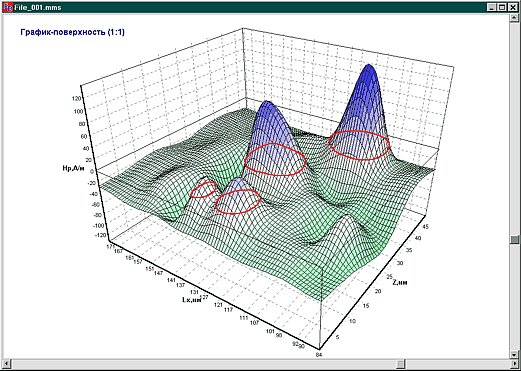

It is used for the analysis and processing of stress concentration detection data, the output of image and data list, the support of 100 data access files, the adjustment of step length, interval, detection length, two-dimensional, three-dimensional and polar coordinate graphic display.

MM-Systea can process several residual magnetism distribution curves at the same time and manage the curve parameters. According to the residual magnetism square curve (Hp curve), the program will automatically form the Hp functional differential curve (Dx curve) to characterize the stress concentration level. Accordingly, according to the detection method, an ultimate stress concentration region (damage development region),

The MM-System can process the data obtained by the stress concentration detector after the computer is reset,

Data entered directly from a computer keyboard. This procedure also allows for editing of the data.

Depending on the user's wishes, the graph can be printed out on a printer or written in a scanning curve format (BMP) for further processing with the help of other programs (e.g. MS Word).

5. Brief description of the process of using metal magnetic memory method to detect buried pipelines

1. Firstly, the stress concentration detection system of buried pipeline is used to diagnose the buried pipeline by non-contact magnetic measurement.

2. Excavate the area where abnormal signals are found.Mark the position in the.

3.Carry out visual inspection at the excavation and contact detection with the buried pipeline stress concentration detection system, and find the stress concentration

4. Use the buried pipeline stress concentration detection system to determine the exact location of the stress concentration area on the surface of the pipeline.

5. After the anticorrosive coating is removed, ultrasonic flaw detection, thickness measurement and penetration detection shall be carried out in the stress concentration area, weld and adjacent parts to find out the defects and measure the wall thickness.

6.Measure the hardness of the material at the location of the stress concentration zone according to the relevant standards.

6. Application Scope of Buried Pipeline Stress Concentration Detection System

1. External corrosion detection

2. Internal corrosion detection

3. Leakage location

4. Crack detection

5. Abnormal detection of welding relay (as shown in the figure: misalignment of circumferential weld: the measured misalignment has reached 47% of the pipe wall thickness)

7. Detection cases using this technology:

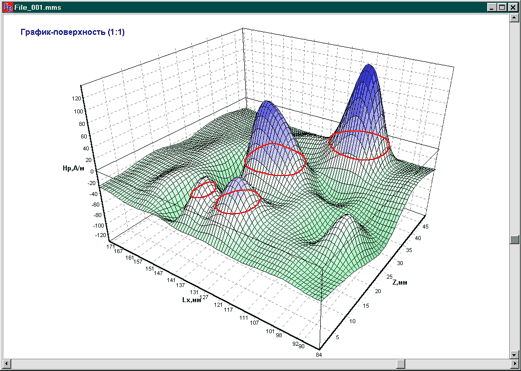

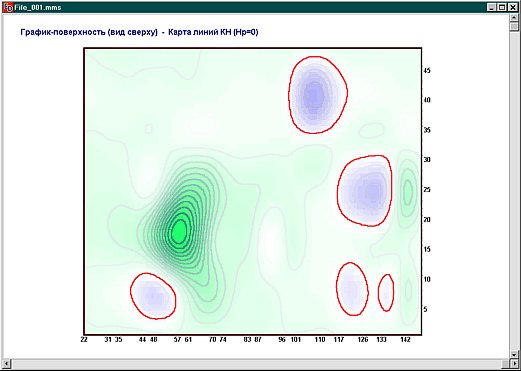

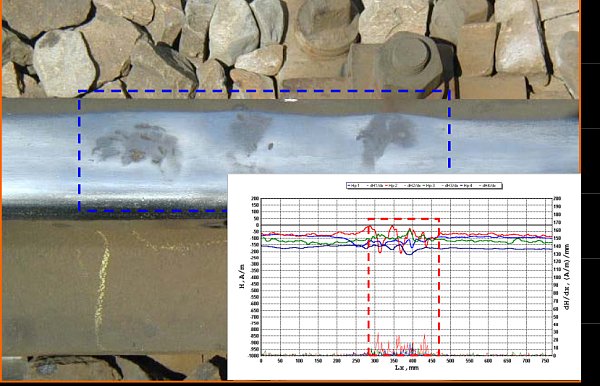

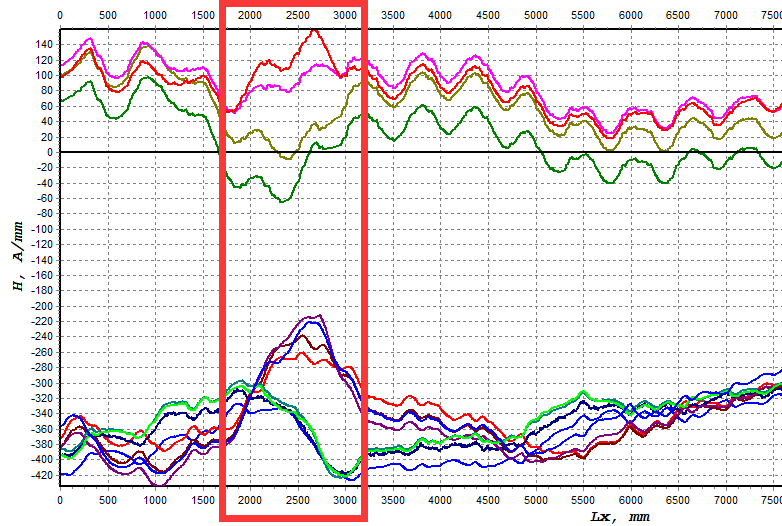

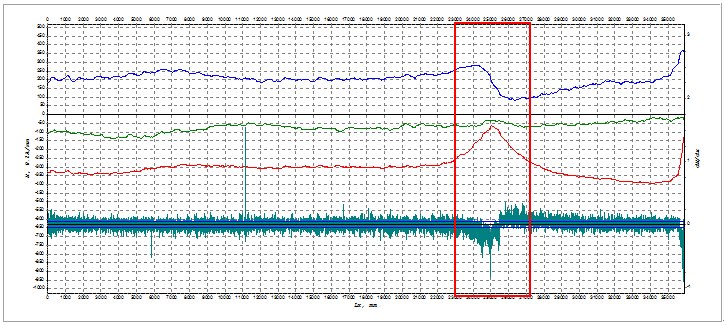

The following is the magnetic field distribution map of the 36m pipeline of the four parallel oil pipelines from the South Reservoir in the first reservoir area of Xinjiang.

Magnetic Field Distribution of Buried Pipeline

Test results

The detection length is about 36 meters, and abnormal signals appear at 23-28 meters from the starting point of scanning. About 8-13m away from the scanning end point, excavation and re-inspection are required.

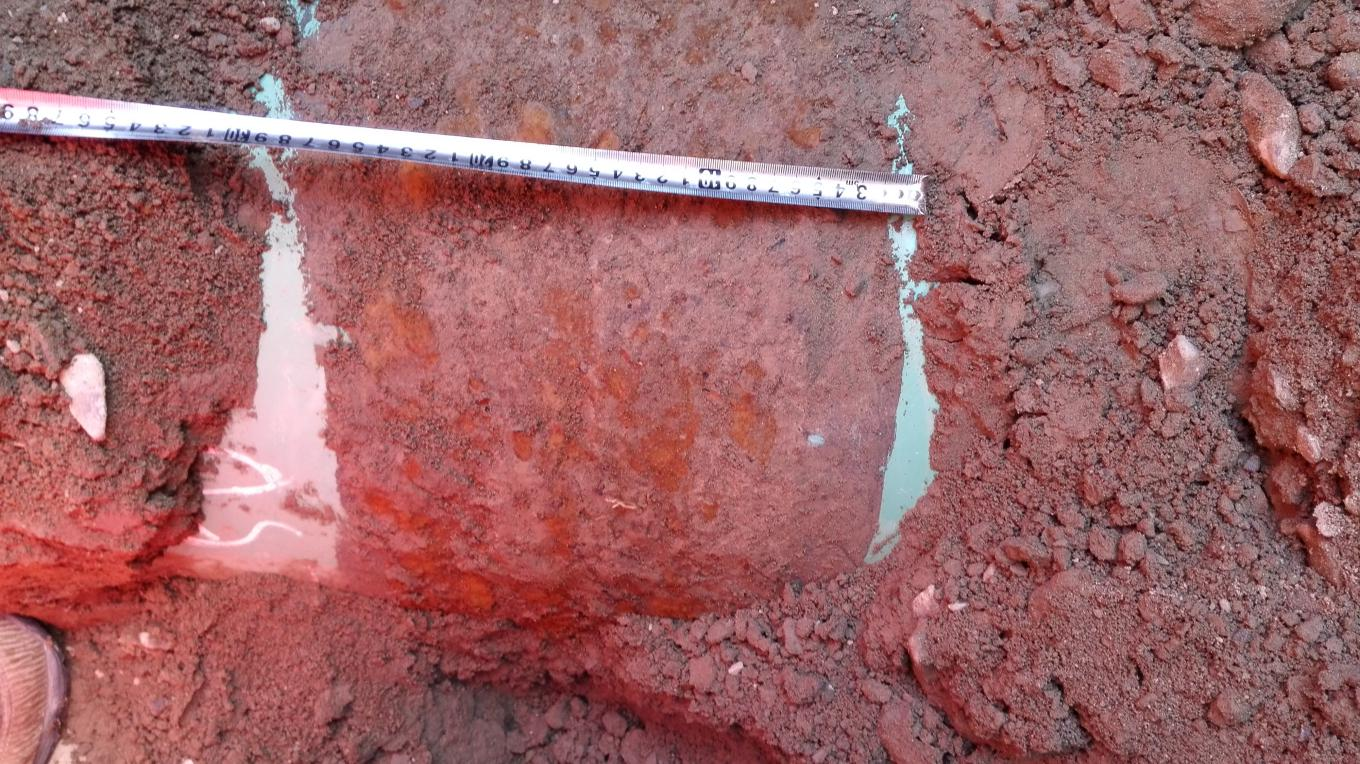

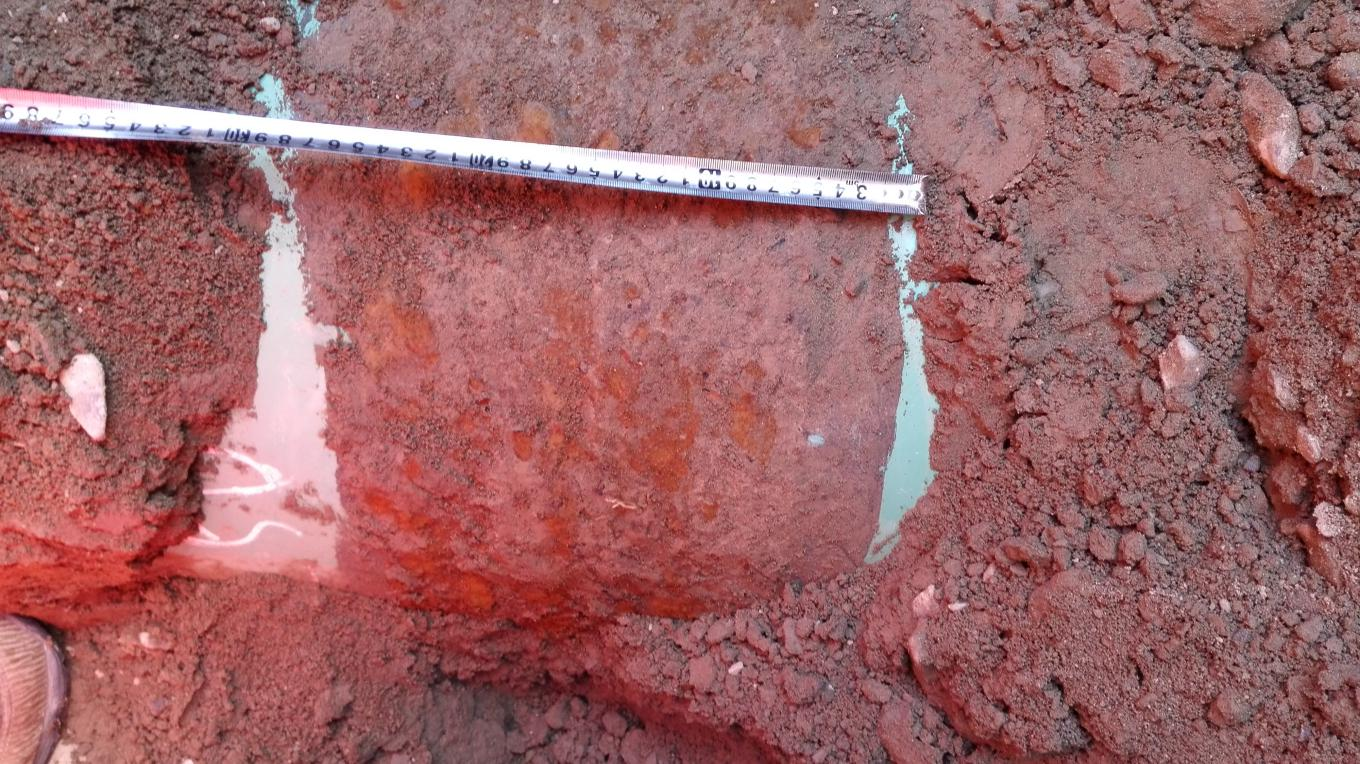

Pictures of excavation site

After excavation, it is found that there is no anticorrosive coating in the 30cm section.

Corrosion of pipe surface before cleaning

Surface corrosion before cleaning:(Corrosion pit)

After cleaning the surface of the pipeline, obvious corrosion pits were found everywhere.