Welcome to Panjin Shunsheng Petroleum Technology Co., Ltd.

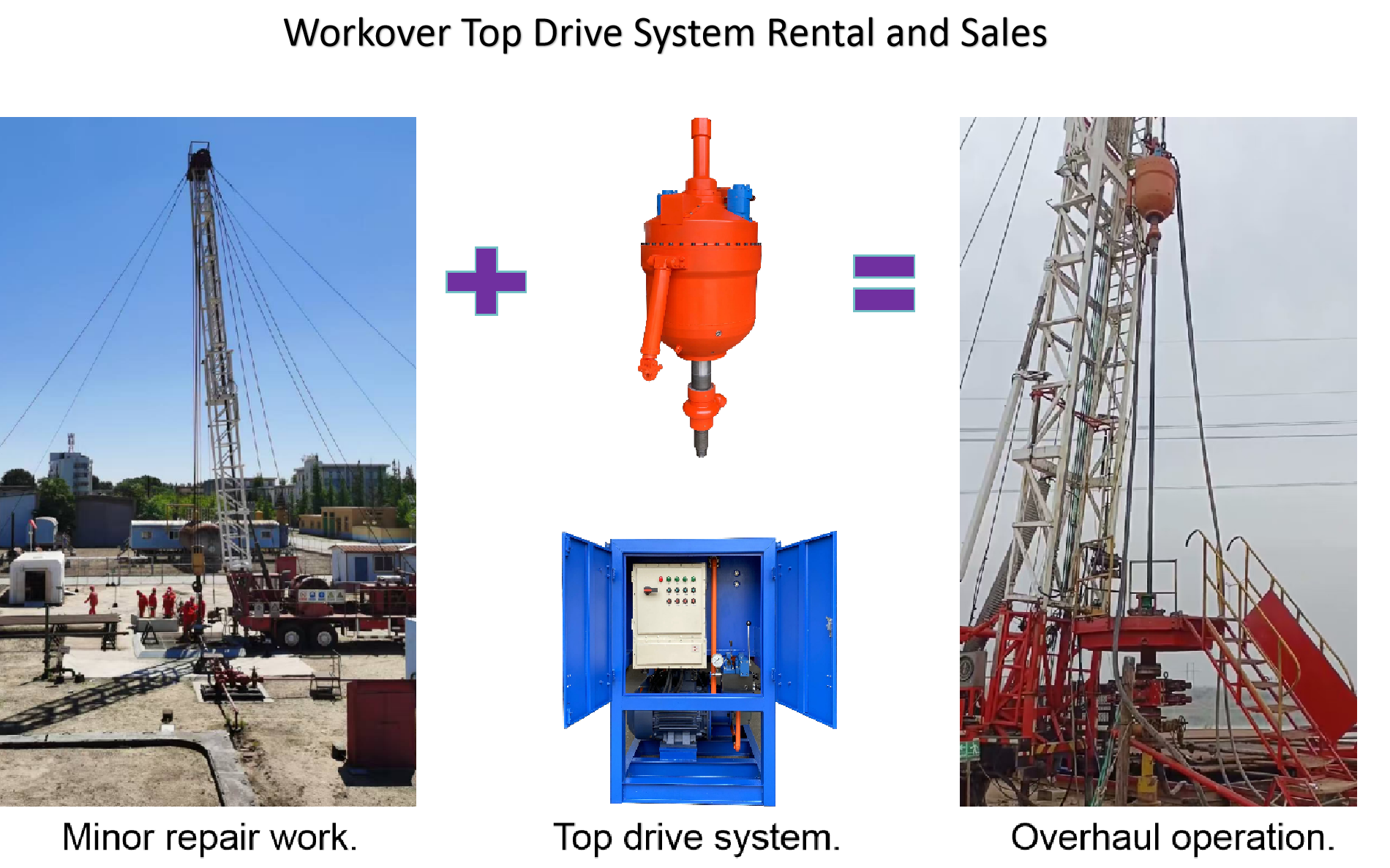

Workover Top Drive System Rental and Sales

Product introduction

Product Technology Introduction

Catalog

I. Background Technology

II. Necessity

III. Features

IV. Advantages

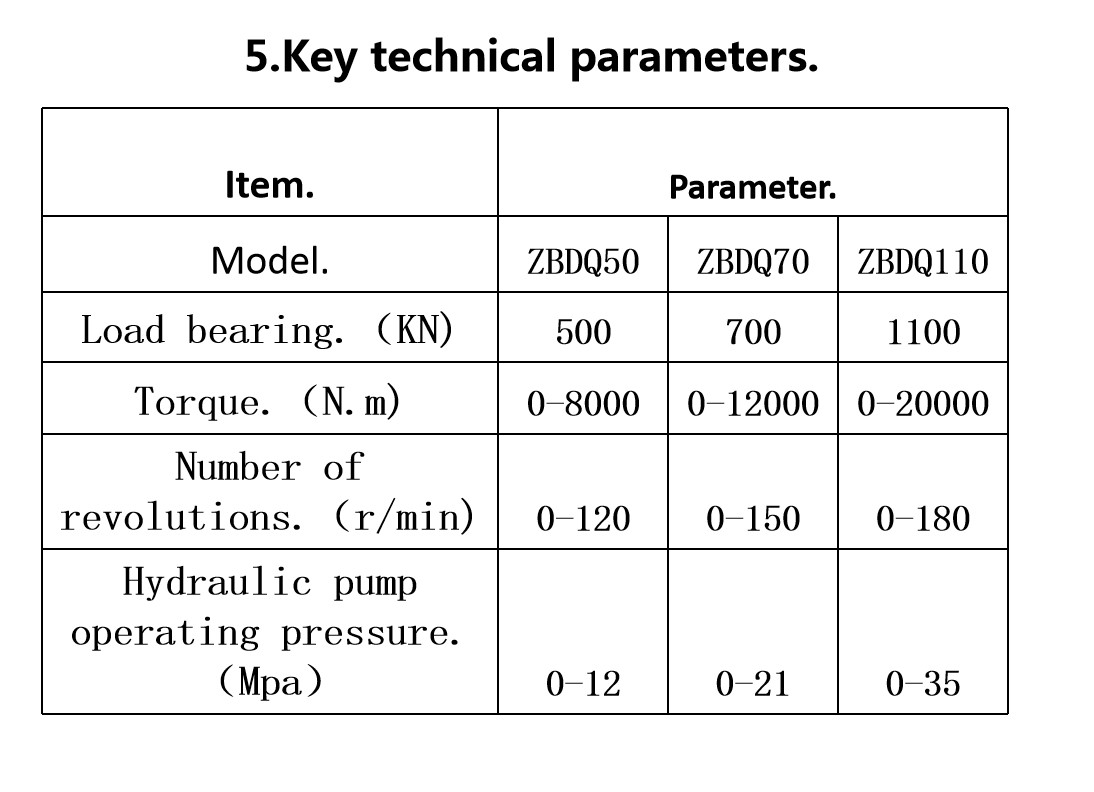

V. Key Technical Parameters

VI. Construction Case

VII. Technical Applications of Top Drive in Workover Operations

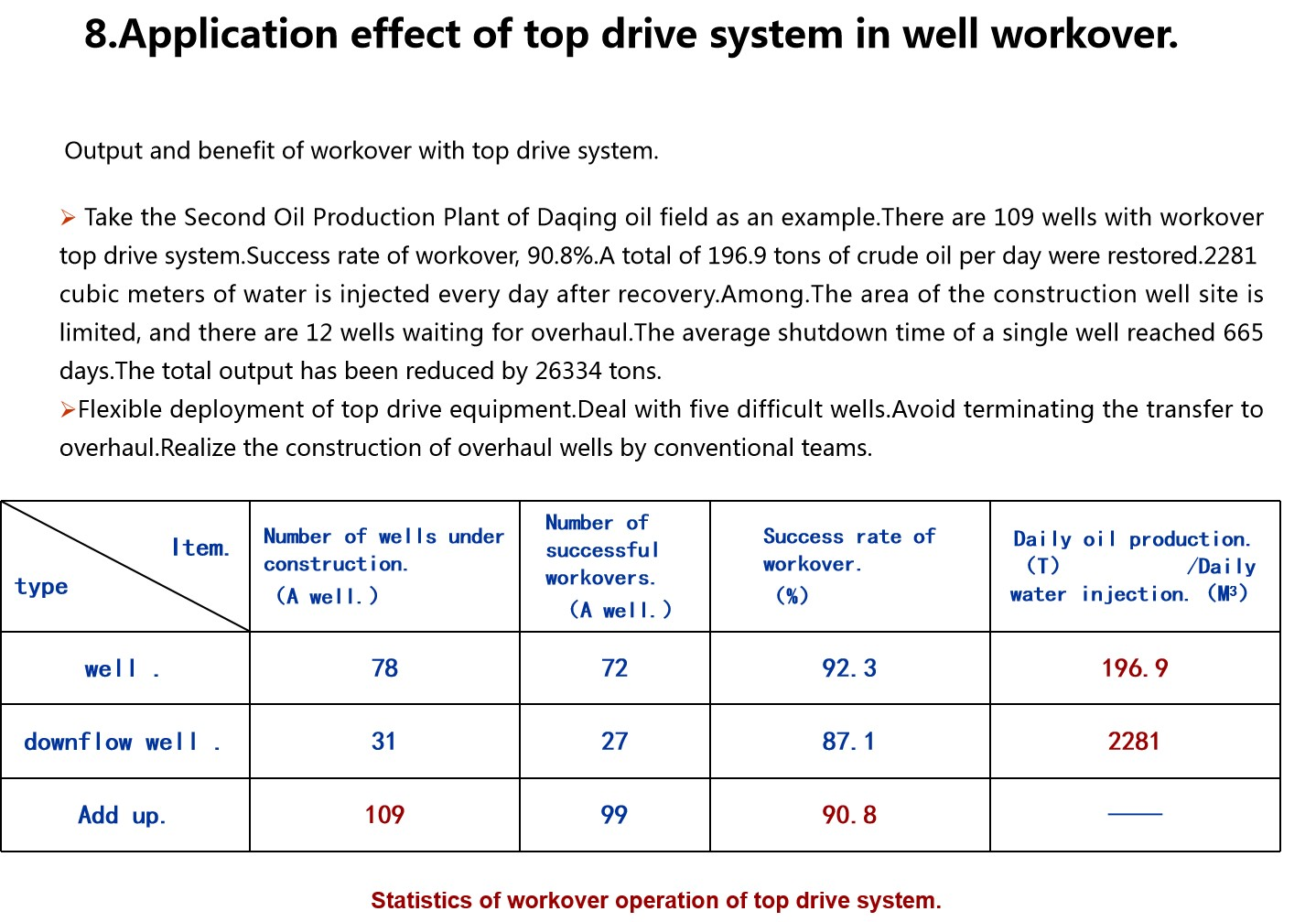

VIII. Application Effects of Top Drive in Workover Operations

I. Background Technology

This equipment has been developed against the backdrop of rapid advancements in technologies such as mechanically driven wellhead rotary tables, hydraulically driven wellhead rotary tables, hydraulically driven swivels, mechanically shifted variable-speed power swivels, hydraulic drive drilling top drives, AC/SCR/DC motor-driven top drives, AC frequency-conversion top drives, and AMT (Automated Manual Transmission) automatic-shift variable-speed drive top drives. Our company independently developed the unique technology, the gear meshing transmission automatic stepless speed changer, and successfully applied it to create the Automatic Stepless Variable-Speed Workover Top Drive. Its primary function is to drive the drill string for drilling and workover operations in downhole environments. During operations, it achieves automatic stepless speed adjustment without shutdown when load torque changes. It also features practical functions such as zero-output soft start and soft transmission

The equipment exhibits excellent constant power characteristics, eliminating the need for power matching calculations. It responds sensitively and timely to speed changes, ensuring high operational efficiency. Its unique zero-output mechanism prevents accidents in the drilling system. The product is characterized by simple structural design, user-friendly operation, cost-effectiveness, safety, and reliability. This technology, independently researched and developed by our company, represents an internationally leading scientific achievement. Notably, breakthroughs in the transmission system have resulted in exclusive patented technology, which has earned two national invention patents and two provincial-level scientific achievement awards.

II. Necessity

Current downhole workover operations have seen improvements in equipment capabilities (including surface circulation systems) and process technologies. However, challenges such as long workover cycles, slow efficiency gains, and technical difficulties persist during field operations:

1. Slow casing deformation repair and poor controllability: Prolonged production in oil wells often leads to casing damage, particularly in heavy-oil wells subjected to multiple rounds of steam injection. This results in casing deformation, fractures, and reservoir damage, rendering the well unproductive. Extended milling period during casing repair increases risks of accidental sidetracking, reservoir destruction, and well abandonment.

2. Limited construction sites in environmentally sensitive areas: Conventional workover rigs struggle to operate in restricted well sites. The workover top drive system addresses this gap, offering a novel construction mode for restricted environments.

3. Challenges in reverse drilling packer operations: Due to reservoir structural complexities, long-term water production in oil and gas wells necessitates reservoir adjustment and redevelopment. During workover operations, original wellbore packers or bridge plugs may need to be drilled out. However, these components (non-drillable in early stages of field development) often remain stuck in the wellbore, necessitating abrasive casing milling. Traditional methods are time-consuming and prone to issues such as prolonged milling, window cutting, and sidetracking.

To resolve these challenges, our company developed the gear meshing automatic stepless variable-speed workover top drive system, applicable to various drilling and workover scenarios, including slim-hole drilling, cement plug drilling, bridge plug drilling, packer drilling, plug drilling, casing milling, core drilling, and casing replacement.

III. Features

1. Wellhead blowout preventer compatibility: A plug valve can be installed below the first drill string joint for instant well closure, ensuring compatibility with well control equipment.

2. Direct use of stands: Reduces tripping time.

3. Simplified design: Eliminates components such as frequency converters, clutches, brakes, synchronizers, gear shifters, load-sharing mechanisms, and constant-speed output mechanisms, reducing energy consumption and operational costs.

4. Zero-output capability: Ideal for operations with frequent load fluctuations, transient high peak power, or impact/sticking risks. In case of sticking, the drill can be lifted immediately for high-speed rotation without releasing drill string torque, preventing tool detachment and ensuring safety for equipment, drill strings, and wells.

5. Constant power characteristics: Automatically reduces speed under high torque and restores high speed under low torque. Drilling speed for cement plugs is several times faster than screw drilling tools.

6. No circulation medium restrictions: No filtration required at the inlet.

7. Low reverse torque: Automatically balanced by the top drive’s internal mechanism, simplifying operation and maintenance.

8. Fully automated operation: Automatic rotation control and make/break functions eliminate manual intervention.

9. Cost-effective integration: Compatible with minor workover rigs, reducing ancillary costs.

IV. Advantages

1. Independent hydraulic and circulation systems: Extends service life and simplifies maintenance.

2. Minimized secondary damage: Prevents sticking accidents, ensures precise milling channels, and facilitates reinforcement.

3. Versatile applications: Effective for threading, fishing, casing deformation repair, and complex workover operations in high-risk or sensitive areas.

4. Conventional pipe compatibility: Enables routine operations with standard drill pipes/tubing and rapid wellbore control to prevent blowouts.

5. Compact and automa

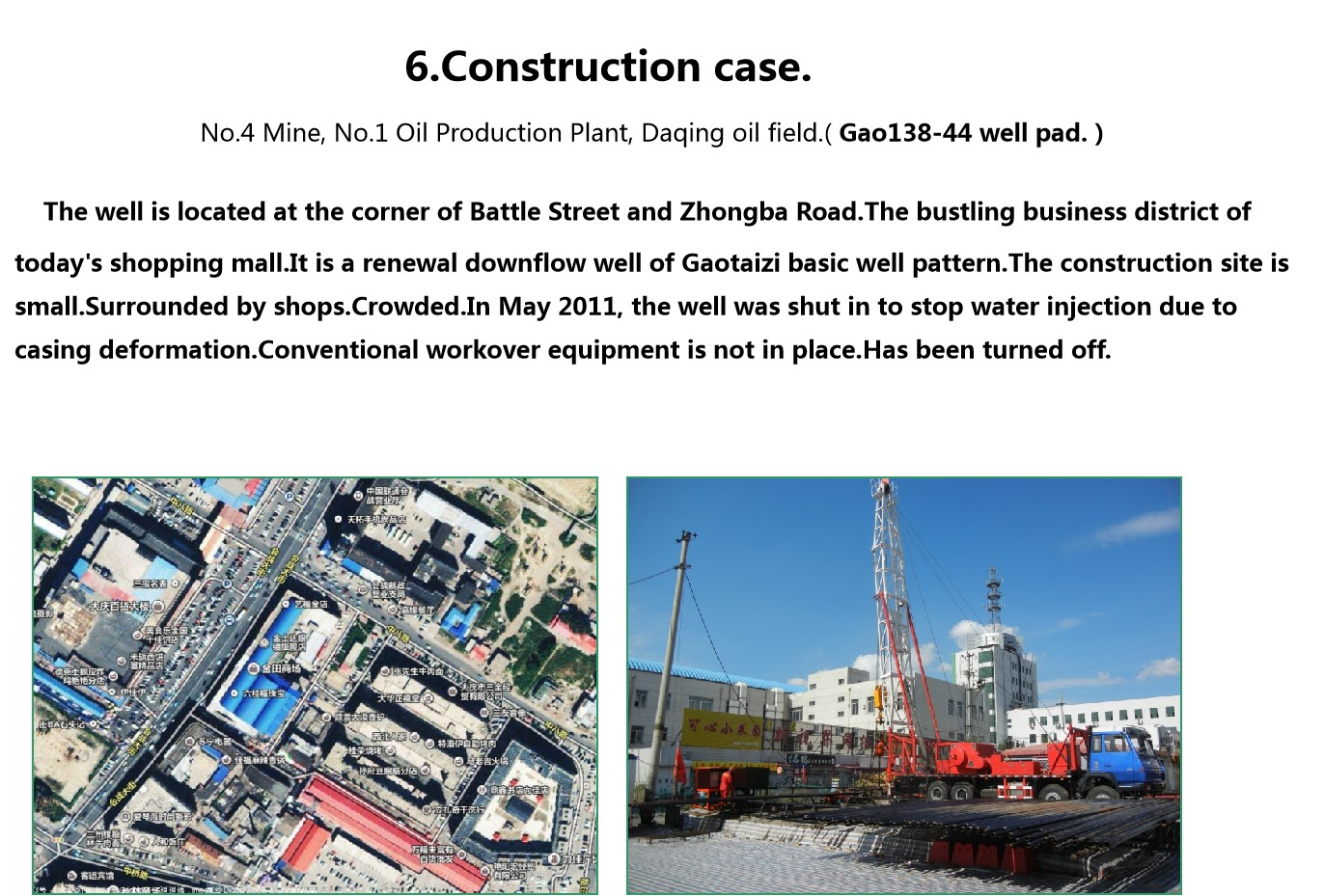

VI. Construction Case

Well Gao 138-Geng 44 (Fourth Mining Area, Daqing Oilfield No.1 Production Plant)

Located in a densely populated commercial area at the intersection of Huizhan Avenue and Zhongba Road, this well is part of the Gaotaizi foundational injection network. Shut down in May 2011 due to casing deformation, conventional workover rigs could not access the site.

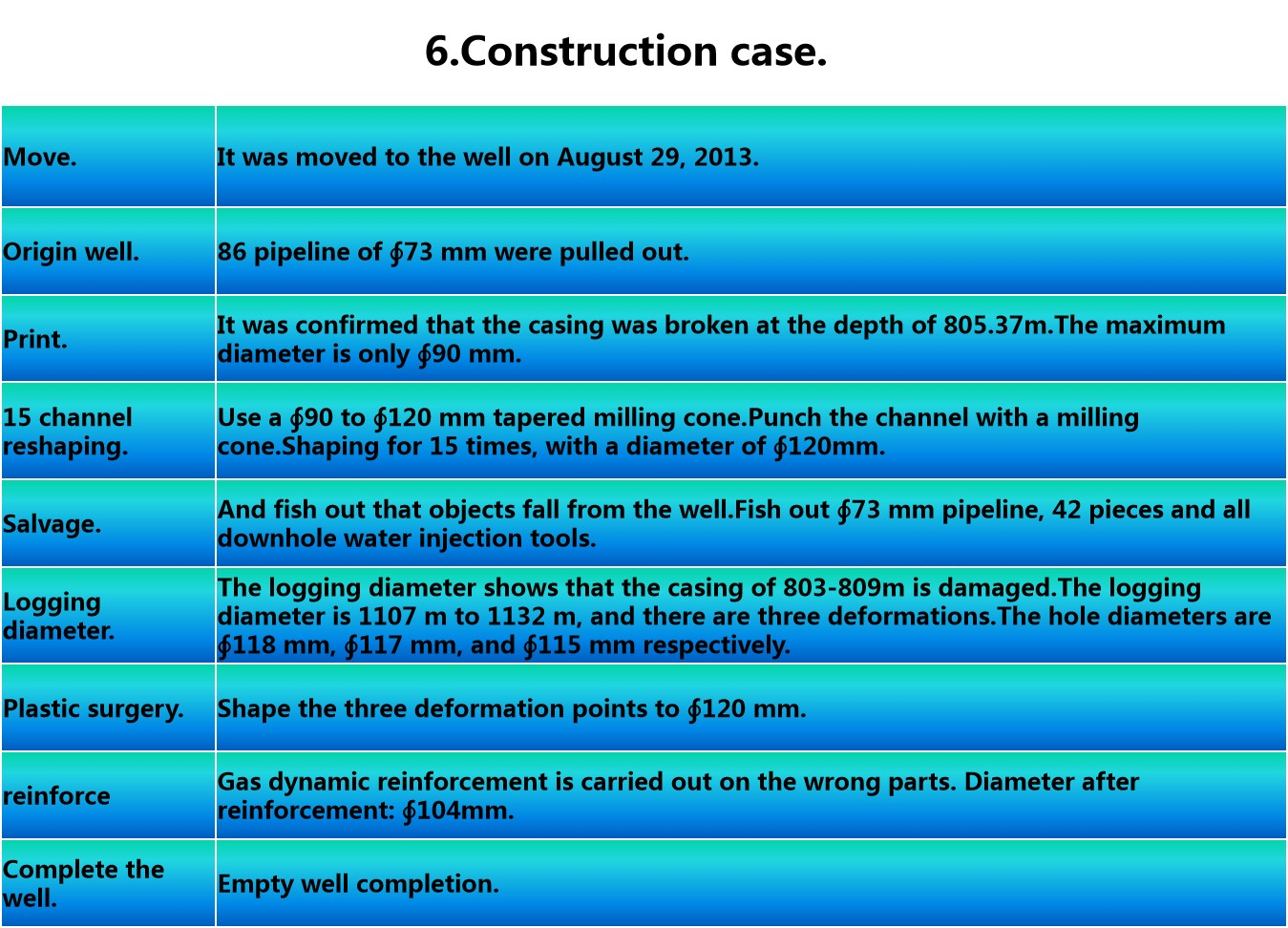

Operations (August 29, 2013):

- Lead impression test: Confirmed casing shear at 805.37 m with a maximum inner diameter of ∅90 mm.

- Channel milling and reshaping: Performed 15 passes with a ∅90–120 mm pear-shaped mill to achieve ∅120 mm.

- Fishing: Retrieved 42 ∅73 mm tubing strings and downhole injection tools.

- Caliper logging: Identified three deformation points (118 mm, 117 mm, 115 mm) between 1132–1107 m.

- Reshaping: Expanded deformations to ∅120 mm.

- Reinforcement: Gas-powered reinforcement at shear point, final inner diameter ∅104 mm.

- Completion: Empty wellbore completion.

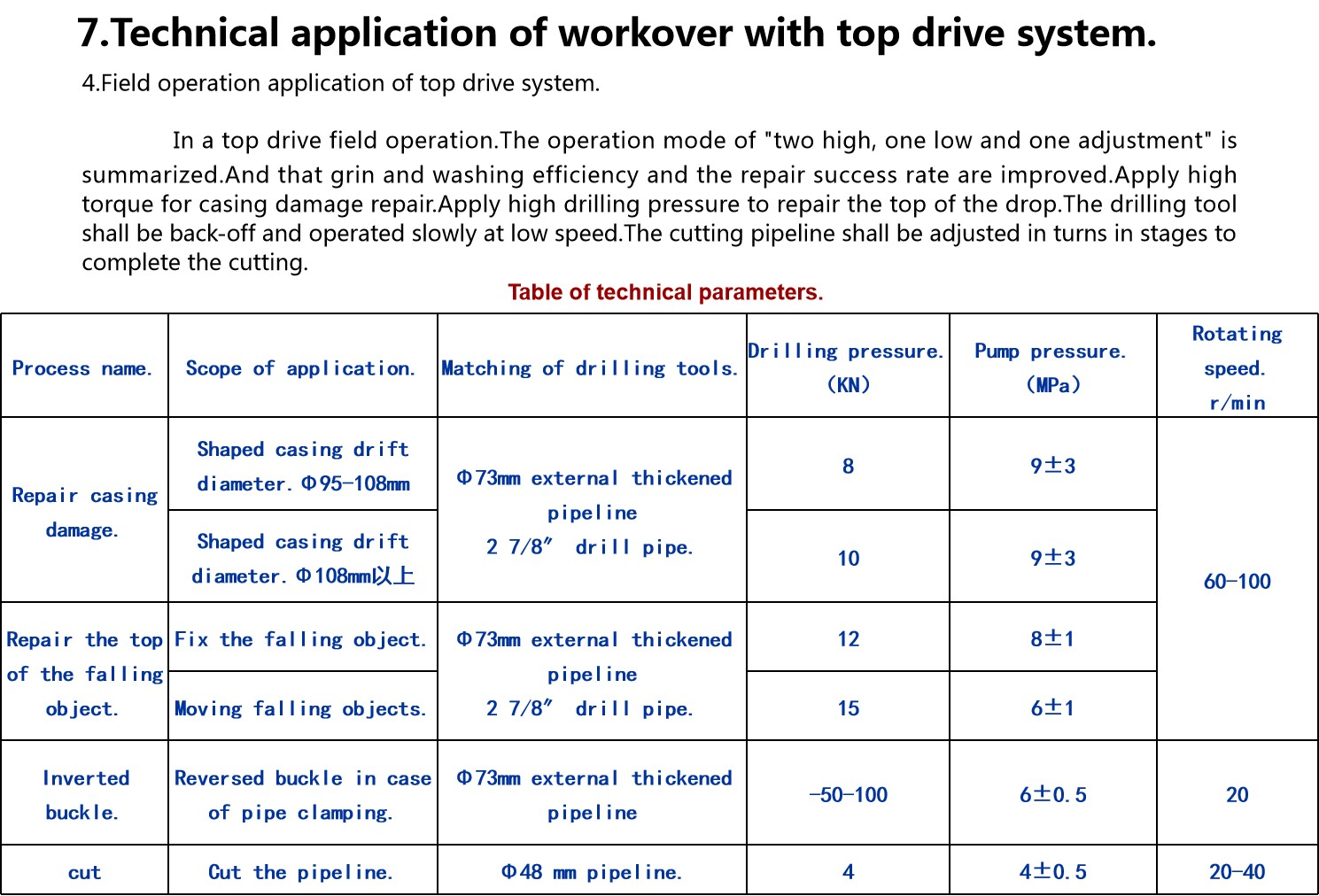

VII. Technical Applications of Top Drive in Workover Operations

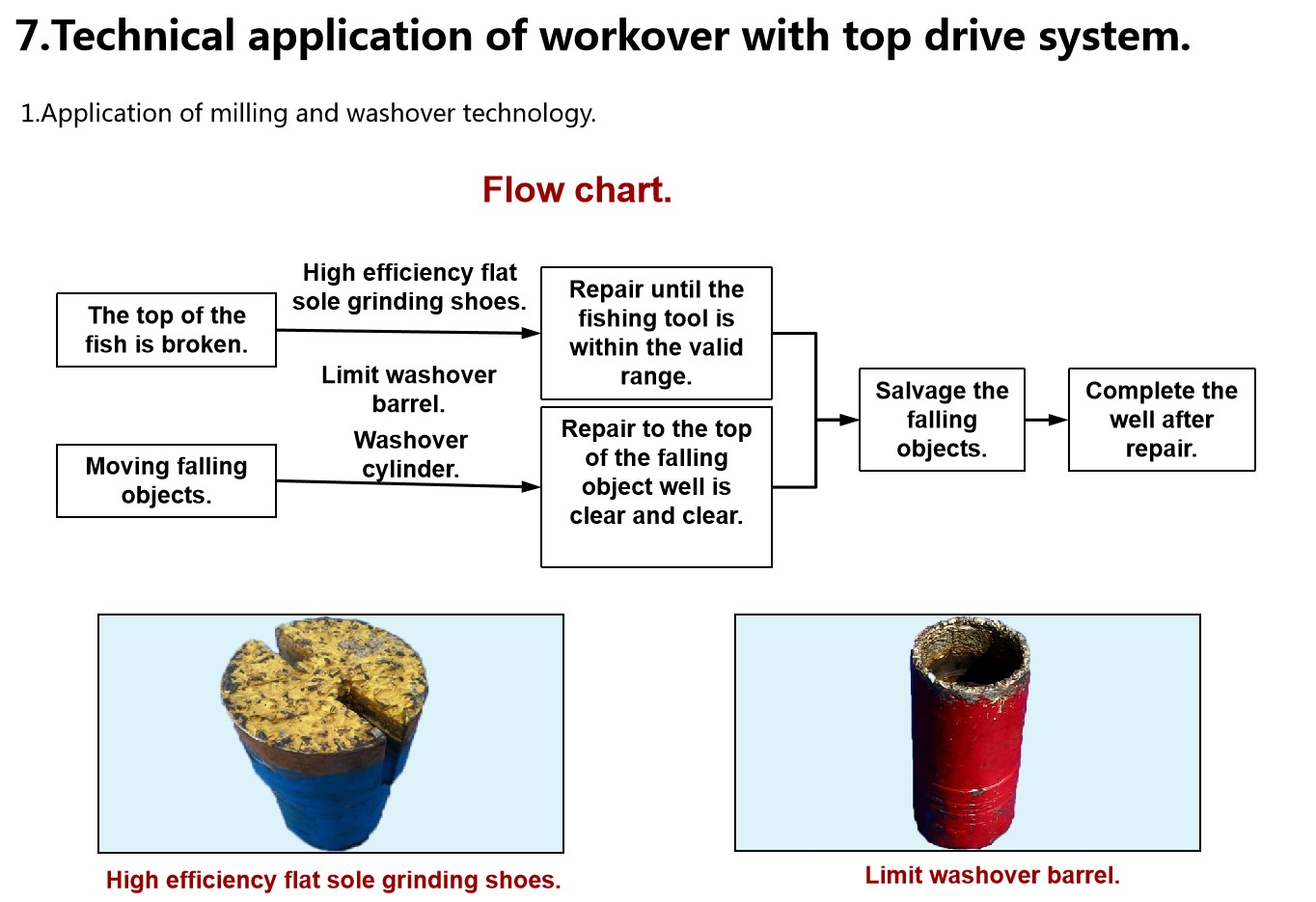

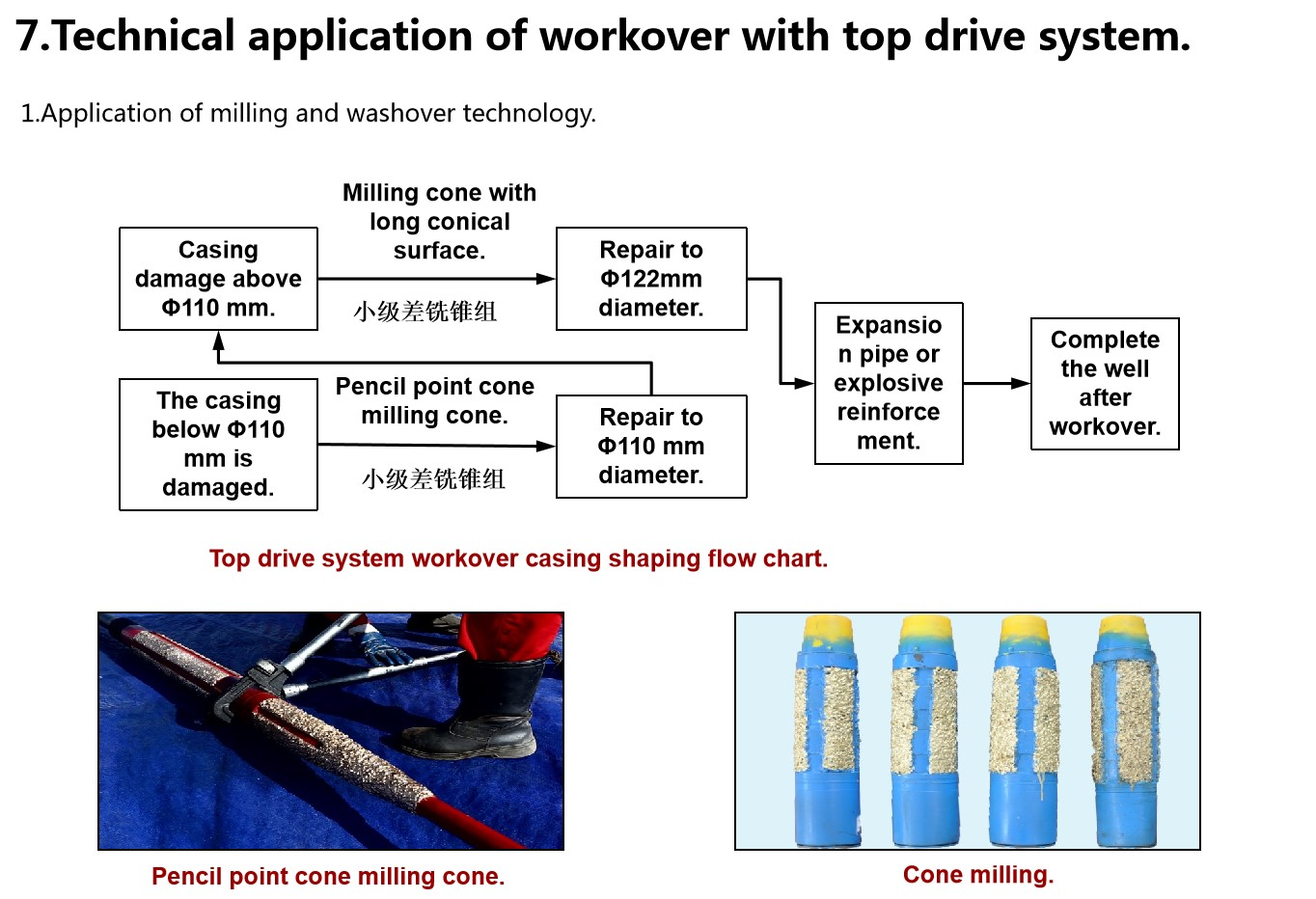

1. Milling and casing milling

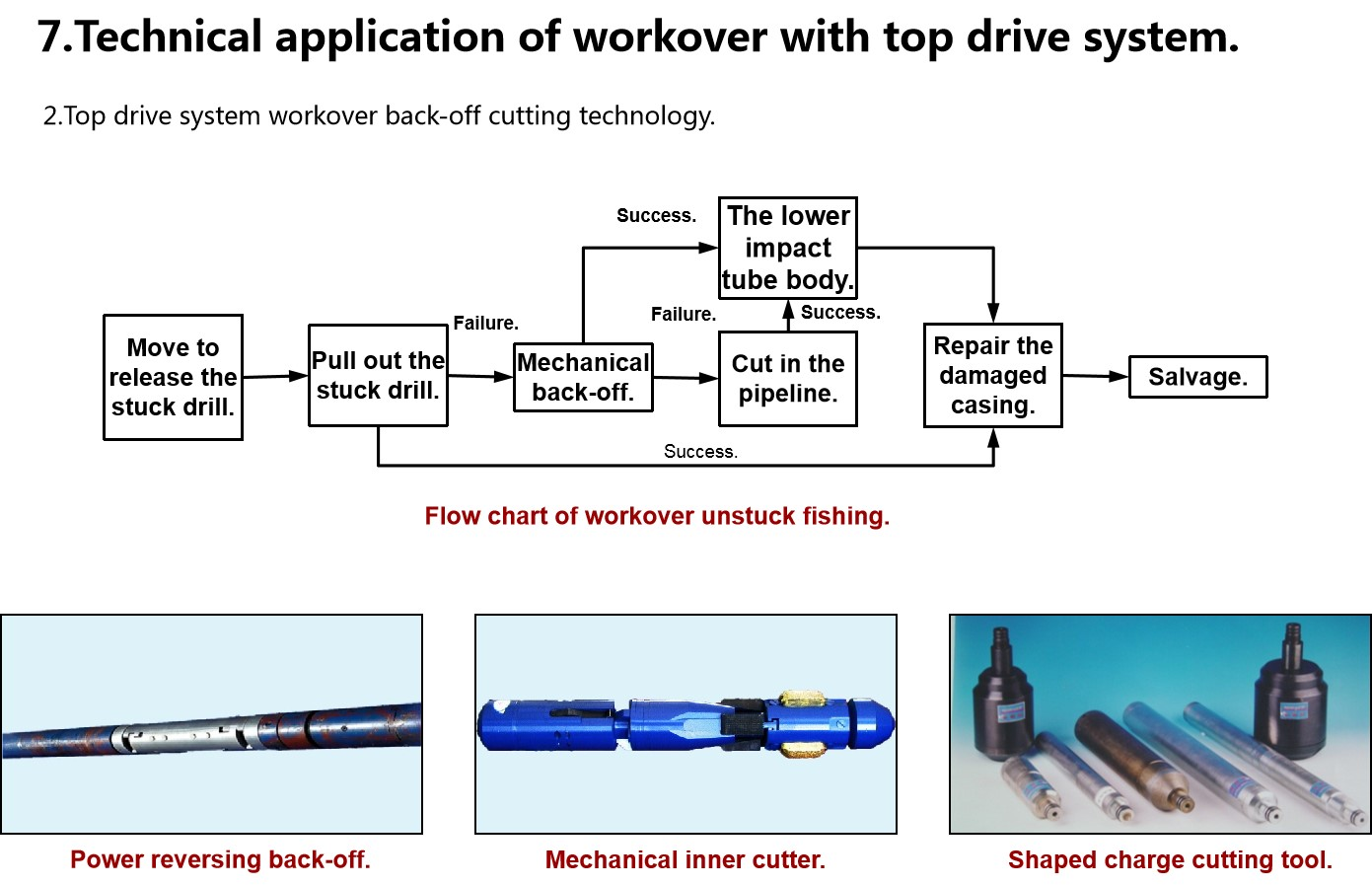

2. Back-off and cutting

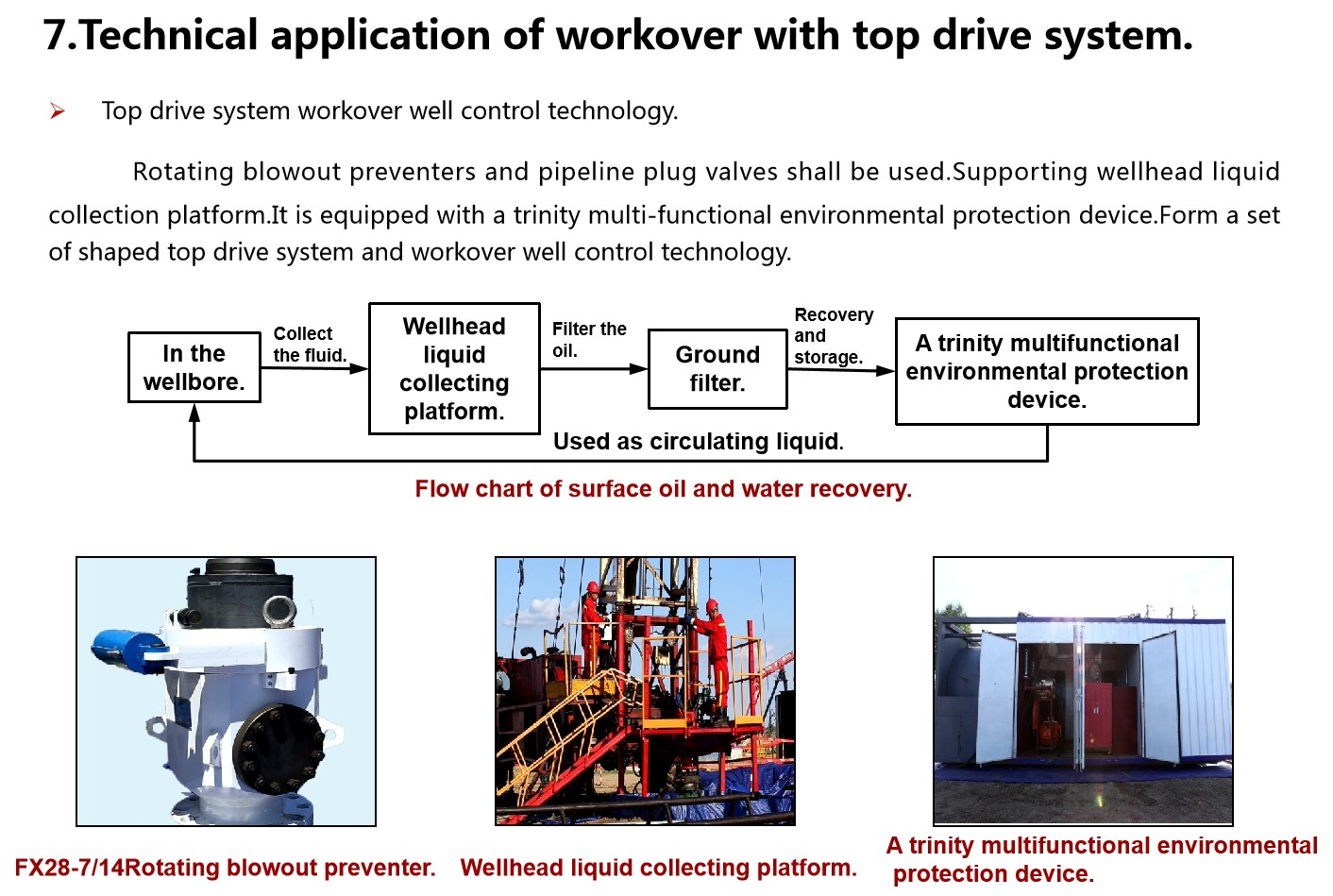

3. Well control

4. Field operation and technology promotion