Welcome to Panjin Shunsheng Petroleum Technology Co., Ltd.

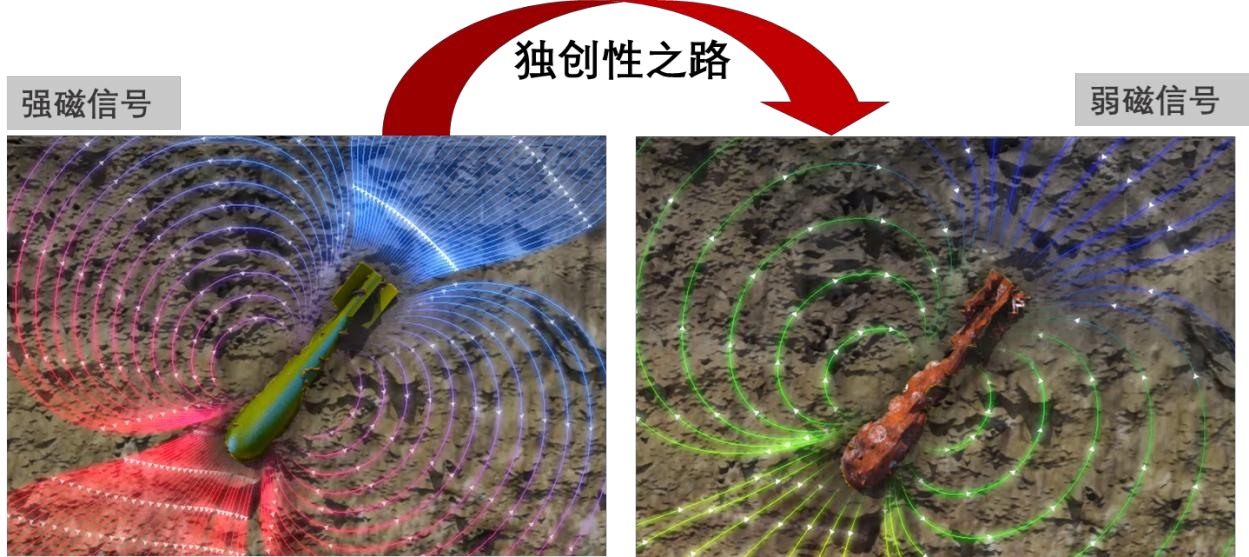

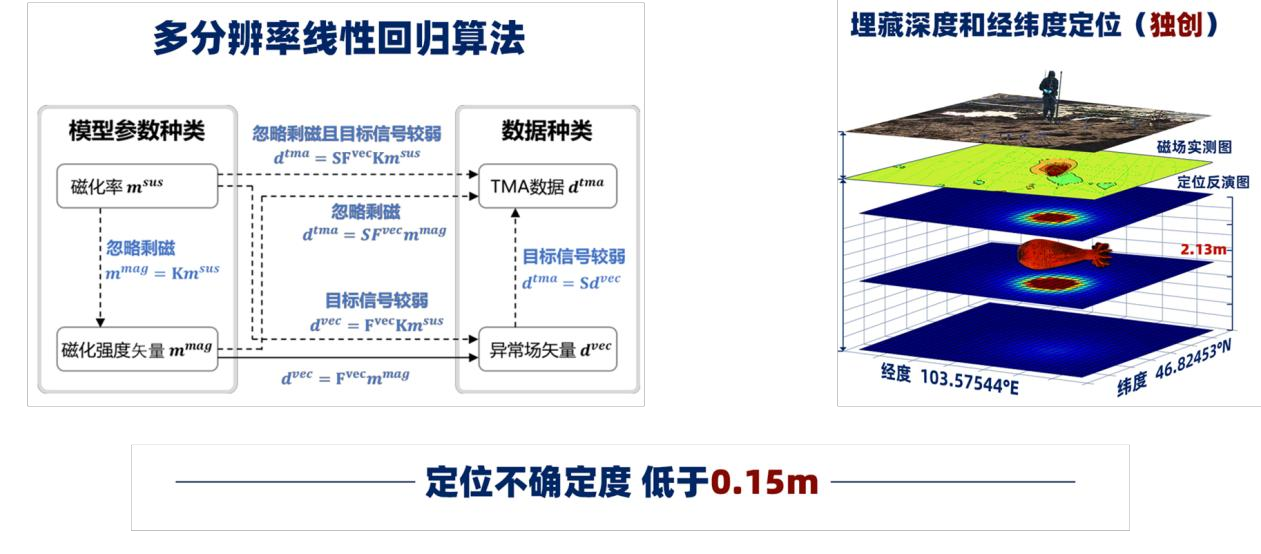

Buried Pipeline Stress Detection System

Contact

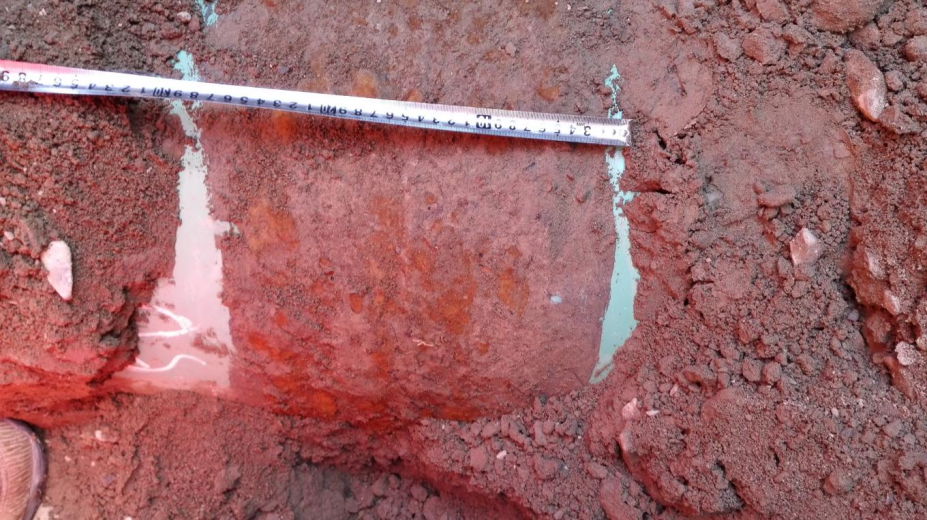

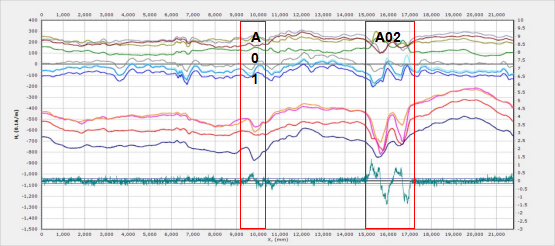

"The non - contact magnetic measurement and diagnostic method is a brand - new process for non - destructive testing of underground oil and gas pipelines. It can determine the metal condition of underground pipelines. It features fast detection speed and low detection cost. There is no need for extensive excavation work. Only the locations with abnormal magnetic field distribution need to be excavated for verification. During the excavation and verification process, there is no need to remove the anti - corrosion coating on the pipeline. The metal magnetic memory method can detect the metal condition of the pipeline body without removing the anti - corrosion coating."

Previous page:No data

Next page:No data

Related suggestion

Online consultation