Welcome to Panjin Shunsheng Petroleum Technology Co., Ltd.

Magnetic Flux Leakage Detection Technology

Contact

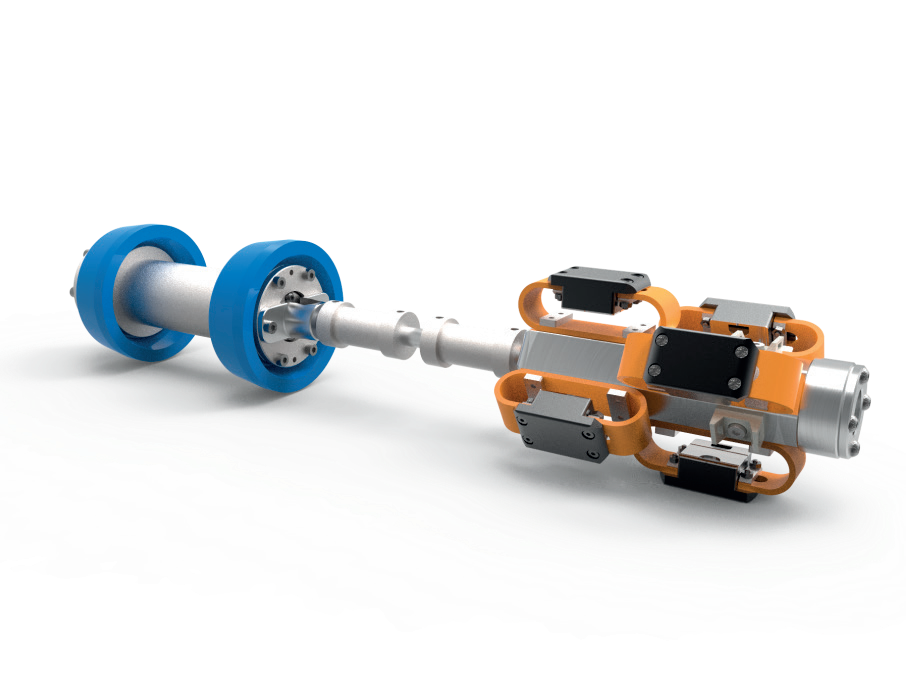

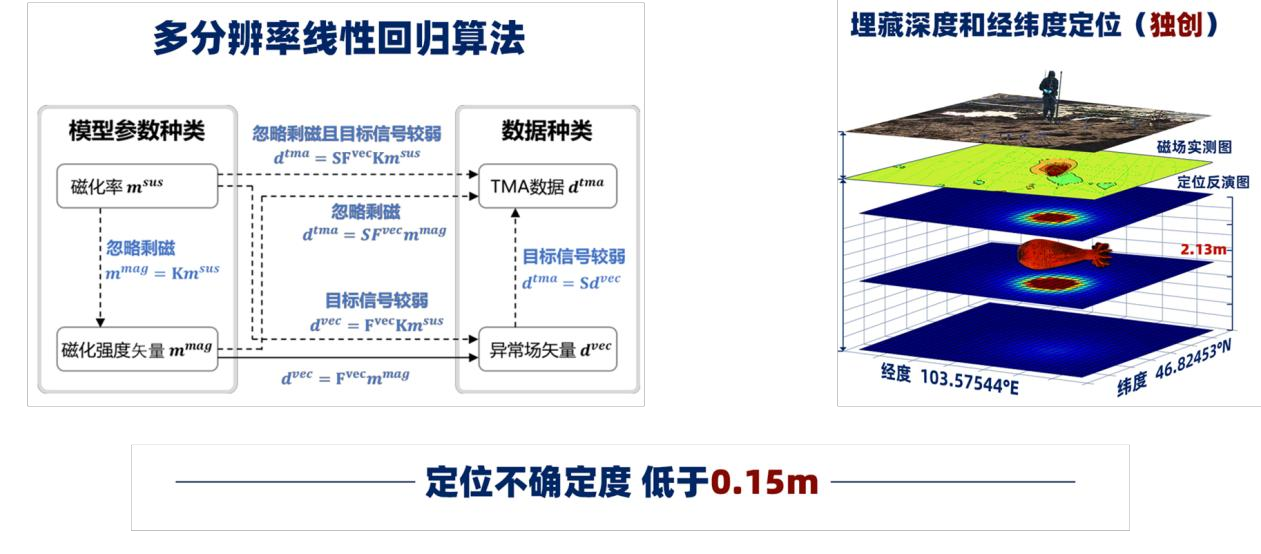

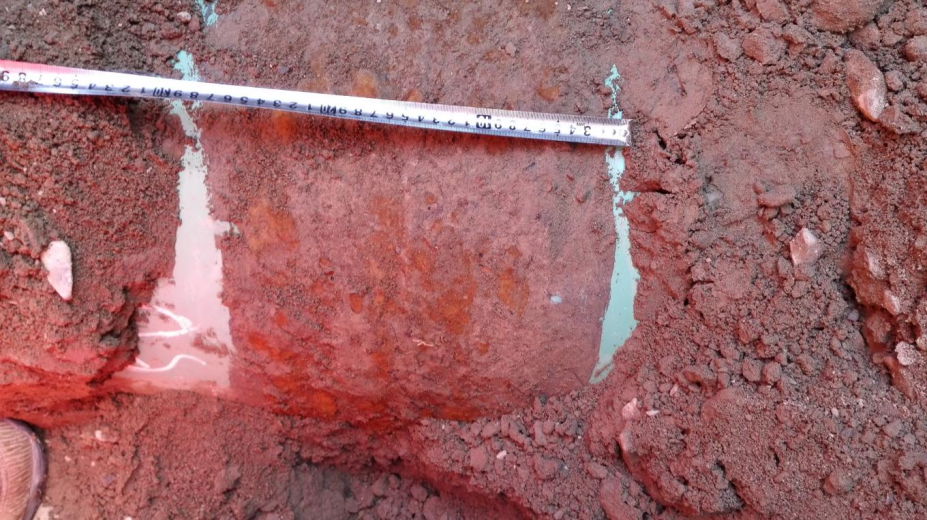

"Magnetic flux leakage detection technology is widely recognized in the industry due to its strong environmental adaptability, especially its high boundary quantification accuracy for contour - type defects. However, due to issues such as magnetic field distribution characteristics, sensor arrangement density, and magnetic permeability distortion in the heat - affected zone, magnetic flux leakage detectors have a high miss rate for magnetic field - parallel cracks, pinholes, and defects at circumferential welds, causing confusion in pipeline integrity management. The electromagnetic holographic internal detection technology can greatly improve defect detection capabilities through means such as ultra - dense sensor arrangement, eddy current sensitivity to cracks, and multi - physical signal complementarity. The 'electromagnetic holographic pipeline internal detection instrument' is equipped with the latest generation of'magnetoelectric composite heterogeneous field multi - functional sensors' with complete independent intellectual property rights, enabling one - time full detection of three types of pipeline defects 'corrosion, cracks, and wall thickness changes', improving the credibility of pipeline health assessment results, reducing costs, and shortening time. The detector is equipped with an ultra - dense caliper arm and a pipeline axial stress concentration diagnosis system, and can optionally be equipped with an ultra - high - precision IMU. It can quickly scan pipeline defects over long distances, draw pipeline maps, and the upper - computer expert system based on multi - physical defect data can greatly improve defect reading and classification capabilities, providing pipeline health reports for customers in the shortest time."

Previous page:No data

Next page:No data

Related suggestion

Online consultation